Project Overview

Challenge:

Rehabilitate existing 250 linear feet of aging chilled water lines installed behind structural members and other utility lines within difficult-to-reach and inaccessible spaces in the Art Building.

Solution:

Utilize NuFlow NuLine epoxy barrier coating technology to efficiently restore pipe functionality, ensuring the chilled water system’s effectiveness with minimal structural impact.

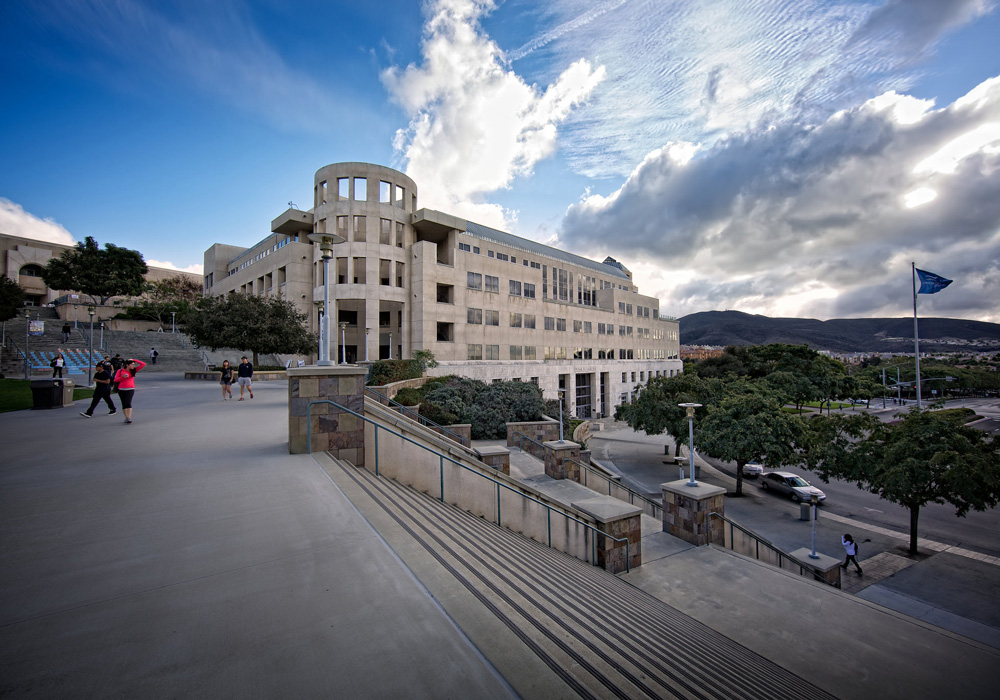

Location: San Marcos, CA

Client Background and Project Scope

The Art Building at California State University San Marcos (CSUSM) experienced efficiency issues with its chilled water system due to deteriorating supply and return lines. Spanning approximately 250 linear feet of 2″, 3″, and 4” black and carbon steel welded and flanged pipe, the project aimed to restore these critical components without extensive demolition or replacement.

Key objectives included ensuring the project’s seamless execution amidst active university operations and leveraging advanced coating technology to extend the piping system’s lifespan with minimal demolition to mechanical chases.

Method

BHP adopted a comprehensive approach, beginning with thorough cleaning to achieve optimal surface anchor tooth conditions for coating adherence. A meticulous drying process followed, ensuring moisture removal to prevent future corrosion.

Quality control was paramount, involving precise temperature and humidity monitoring or the pipelines during the epoxy mixing and application stages. The two-part epoxy underwent careful preparation, including a premixing phase and an induction period, before its application through a strategic inline system, allowing for even distribution within the pipes. Two coats were applied.

The project required working in sensitive areas, including ceiling spaces near restrooms and the rooftop, necessitating careful planning and execution to minimize impact on the university’s daily operations.

Outcome

The application of Nu Flow Nu Line epoxy barrier coating technology successfully rehabilitated the Art Building’s chilled water lines, enhancing the efficiency and reliability of the air conditioning system. This innovative solution not only extended the piping system’s lifespan but also upheld CSUSM’s commitment to operational excellence and sustainability.

The project demonstrated BHP’s expertise in navigating complex logistical challenges, and delivering high-quality outcomes with minimal disruption to client operations. As a result, the Art Building at CSUSM now benefits from a modernized infrastructure component essential for its daily functions, showcasing the potential of advanced restoration technologies in educational settings.